Technology

Advanced Graphene Solutions

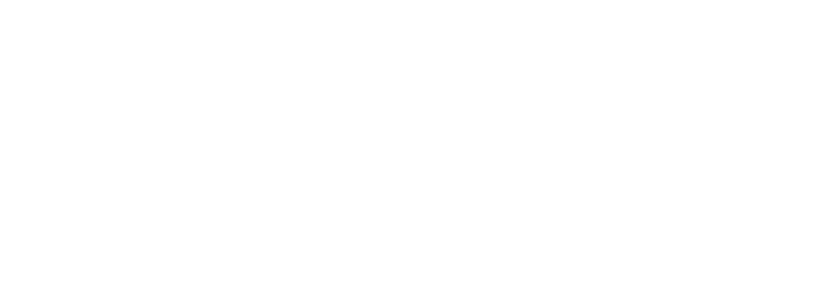

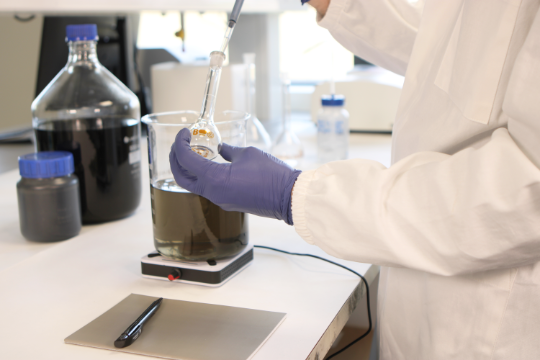

At Danish Graphene, we specialize in producing high-quality, functionalized graphene materials that can be precisely tailored to meet the unique requirements of your product and application. Our proprietary production process allows us to incorporate various chemical modifications onto the graphene’s surface, enhancing its interaction with other materials and optimizing its performance across a range of applications.

Industrializing Graphene

Danish Graphene focuses on flexible, scalable solutions with modular reactor systems, allowing us to quickly adapt production capacity to meet market demand.

Through our proprietary sustainable production method, we deliver a groundbreaking graphene solution that enhances industrial product performance while ensuring consistent production quality to meet industry needs.

Our goal is to achieve a production capacity of several tons of green graphene oxide by 2027, addressing the increasing demand from industrial applications. By 2030, we aim to scale production to several hundred tons, fully industrializing graphene production.

Leveraging our expertise in graphene integration, we collaborate closely with industry partners to ensure seamless integration and maximize the functionality of graphene materials, expanding its applications across various industries.

Applications

Our graphene products are engineered for versatility and can be integrated into a wide range of applications. Whether enhancing mechanical strength, improving thermal or electrical conductivity, or enabling advanced barrier properties, our functionalized graphene solutions help elevate product performance across industries such as energy storage, coatings, composites, and electronics.

Graphene-based additives can improve the strength, durability, and crack resistance of construction materials leading to less material use and thereby CO2 reductions in the industry.

Graphene also benefits processability of materials giving anti-static properties to powders to improve mixing processes and accelerating curing processes reducing production times significantly offering more resilient and sustainable construction solutions.

Graphene’s unique properties — high conductivity, flexibility, and thermal stability — make it an ideal material for next-generation printed electronics. As a sustainable alternative to traditional metal-based inks, our graphene materials enable more reliable and durable solutions for wearable and flexible devices.

Graphene’s impermeable structure significantly boosts the durability of coatings, protecting materials in harsh environments. It offers a sustainable, high-performance alternative to traditional anti-corrosion solutions, reducing maintenance and environmental impact.

Danish Graphene manufactures a graphene paste highly suitable as carbon additive for battery materials. The drop-in paste, readily disperses, and can be directly added to industrial process lines without introducing new steps or processes in production. The graphene additive improves ICE and cycle-life and outperforms single-walled carbon nanotubes traditionally used in the industry.

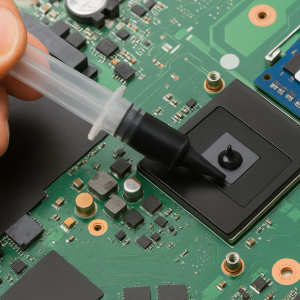

At Danish Graphene, we leverage graphene’s unique thermal properties to develop advanced thermal interface materials. Our two-component epoxy system delivers high thermal conductivity with minimal additive content — and we are continuously expanding our portfolio to meet the growing demands of thermal management applications.

Graphene-enhanced fiber composites can improve the interlaminar strength in composites which is traditionally the weakest point in the material. Adding graphene to the matrix can improve thermal transfer and electrical properties offering new industry opportunities and capabilities.