Graphene ink

Problem

Metal Inks: Limiting Performance, Driving Up Costs

Conductive inks are an integral part of the next generation of electronics where printed electronics gives new opportunities for flexible electronics, smart wearables, and lightweight systems. Current conductive inks are primarily made using silver particles due to high electrical performance, but silver is an expensive material, increasing production costs in manufacturing.

To circumvent this added cost other metals are used such as copper or aluminium but though these materials might solve the cost issue other problems are still present. With metal fillers there is a risk of particle migration which can short circuit electronics or change performance over time. Metal-based conductive inks are brittle and do not withstand thermal cycling or corrosion very well leading to degradation of conductivity and performance.

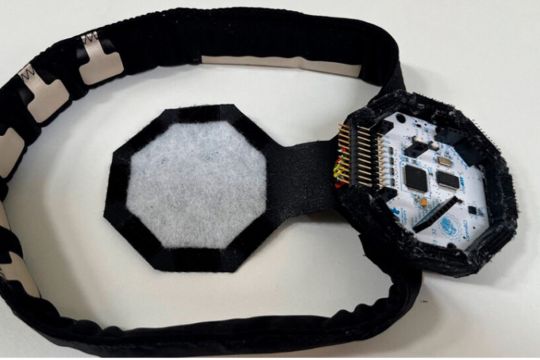

Substrate adhesion, flexibility, and bio compatibility limits the uses and effectiveness of metal-based conductive inks, for example in health monitoring wearables, flexible electronics, and smart textiles.

Solution

Graphene Inks: Flexible Conductivity for Modern Electronics

Graphene is a carbon-based additive with great electrical conductivity properties, is flexible, and biocompatible. Graphene-based inks have great potential to replace metal-based inks due to much higher thermal stability, mechanical flexibility, and no particle migration, solving several of the issues with current ink solutions.

At Danish Graphene a graphene-based conductive ink was developed with an electrical resistance of just 10 Ω/sq with a thickness of 5 µm. These inks can be printed with screen printing on textiles that are stretchable, flexible, and even washable. With the biocompatibility of the graphene additive these solutions can be used for on-body sensors in health monitoring without causing issues for patients.

For the future development of flexible electronics, graphene-based conductive inks offer brand new opportunities.

Customer benefit

Reliability, Adaptability, Sustainability

Sustainable and biocompatible carbon-based additive for conductive inks. Decreases weight, higher flexibility, low electrical resistance, sustainable graphene additives.

Danish Graphene offers sustainably produced graphene materials with a focus on quality and industrialization of graphene. With our experience with graphene, we can also support in development and integration activities.