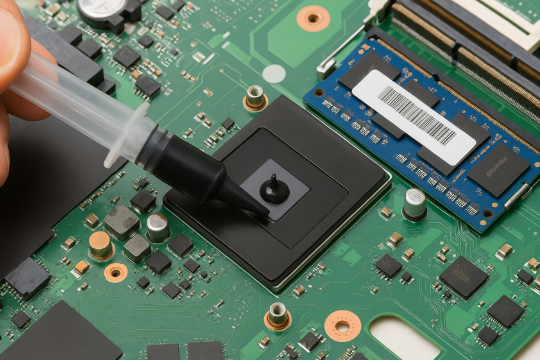

Thermal Interface Material

Problem

Cooling Challenges for High-Performance Systems

Cooling high-performance electronics and industrial equipment is increasingly challenging.

Traditional thermal interface materials, typically based on metal oxides, offer limited performance and design flexibility. As systems become more compact and powerful, overheating risks grow—leading to component damage, system failure, and costly downtime.

Conventional cooling methods are energy-intensive, raise CO₂ emissions, and restrict innovation in system design.

Solution

Graphene: The Future of Thermal Management

Graphene-enhanced thermal interface materials (TIMs) break through the limitations of conventional solutions.

With superior thermal conductivity, lower density, and the ability to form ultra-thin bond lines down to 15 µm, these materials enable more efficient heat transfer and greater design freedom.

They integrate seamlessly into existing systems and are already validated in demanding sectors such as the space industry. Compared to metal oxide-based TIMs—even those with higher documented conductivity—graphene-enhanced alternatives deliver better real-world effectiveness.

The switch to graphene also reduces environmental impact, supporting more sustainable product lifecycles.

Customer benefit

Boost Performance and Sustainability with Graphene

Enhance your system’s thermal performance with graphene-enhanced TIMs. Benefit from improved efficiency, reduced material weight, and a smaller environmental footprint—without sacrificing compatibility or ease of integration.

Unlock new design possibilities and build more reliable, high-performing, and sustainable solutions.