Watt & Well approves Danish Graphene's GET AE in Rigorous Testing! 🔧

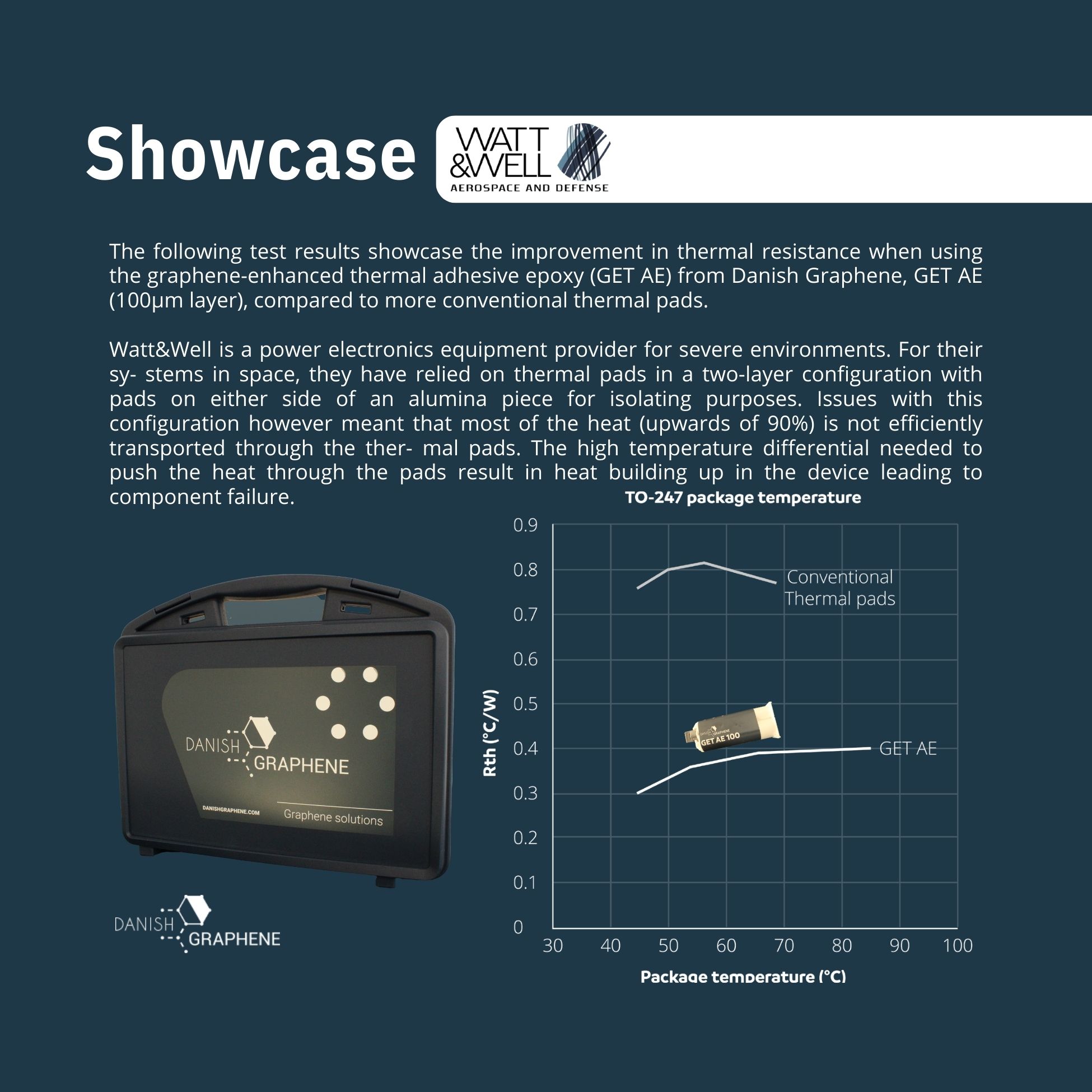

The following test results showcase the improvement in thermal resistance when using the graphene-enhanced thermal adhesive epoxy (GET AE) from Danish Graphene, GET AE (100µm layer), compared to more conventional thermal pads.

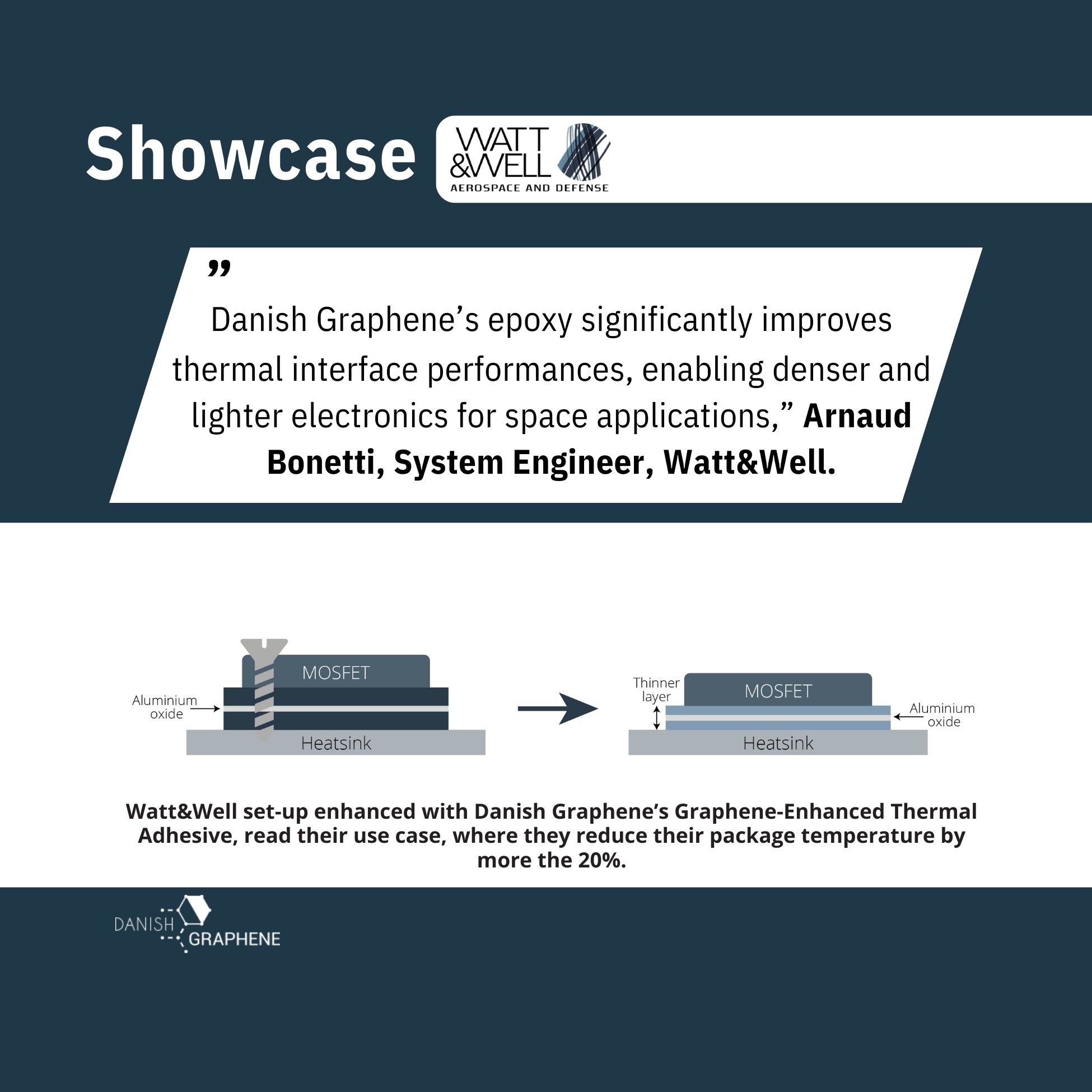

Watt&Well is a power electronics equipment provider for severe environments. For their systems in space, they have relied on thermal pads in a two-layer configuration with pads on either side of an alumina piece for isolating purposes. Issues with this configuration however meant that most of the heat (upwards of 90%) is not efficiently transported through the thermal pads. The high temperature differential needed to push the heat through the pads result in heat building up in the device leading to component failure.

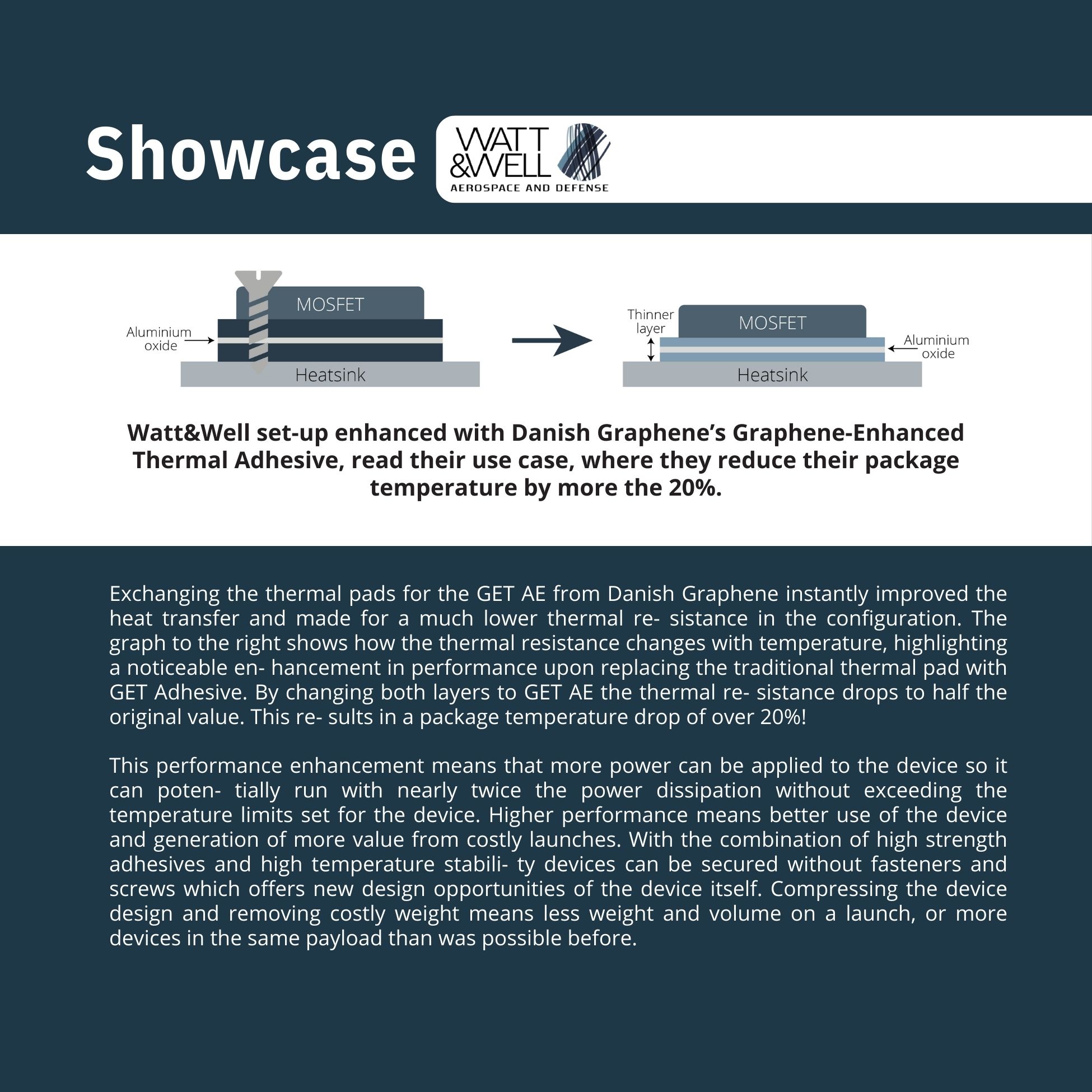

Exchanging the thermal pads for the GET AE from Danish Graphene instantly improved the heat transfer and made for a much lower thermal resistance in the configuration. The graph to the right shows how the thermal resistance changes with temperature, highlighting a noticeable enhancement in performance upon replacing the traditional thermal pad with GET Adhesive. By changing both layers to GET AE the thermal resistance drops to half the original value. This results in a package temperature drop of over 20%!

This performance enhancement means that more power can be applied to the device so it can potentially run with nearly twice the power dissipation without exceeding the temperature limits set for the device. Higher performance means better use of the device and generation of more value from costly launches. With the combination of high strength adhesives and high temperature stability devices can be secured without fasteners and screws which offers new design opportunities of the device itself. Compressing the device design and removing costly weight means less weight and volume on a launch, or more devices in the same payload than was possible before.